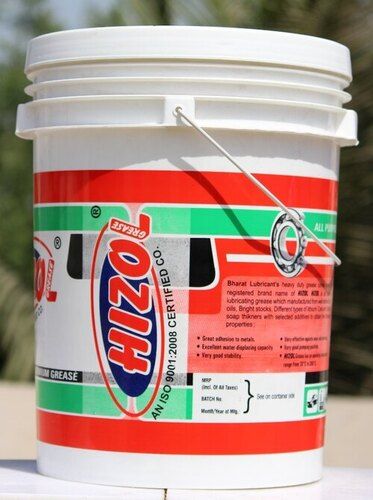

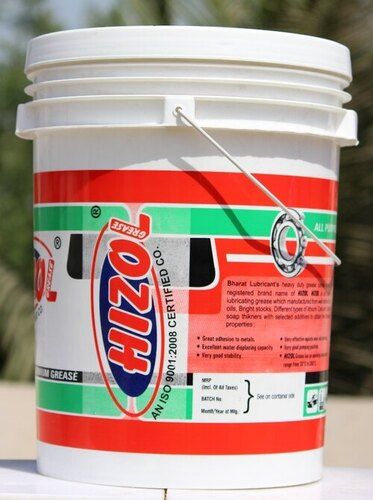

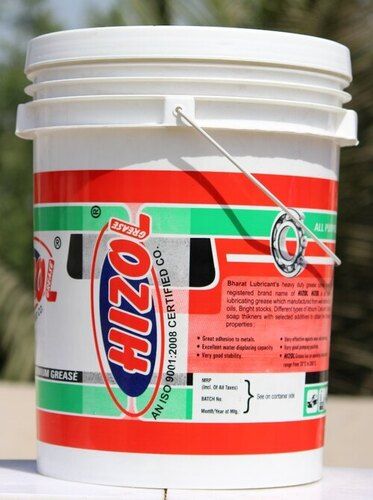

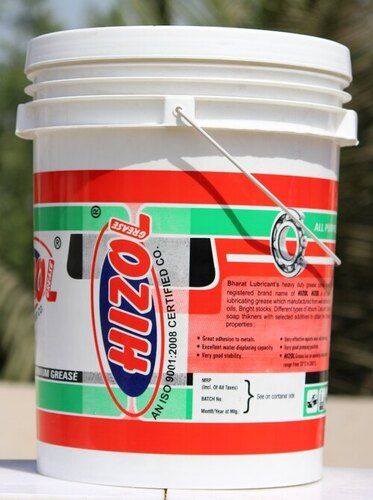

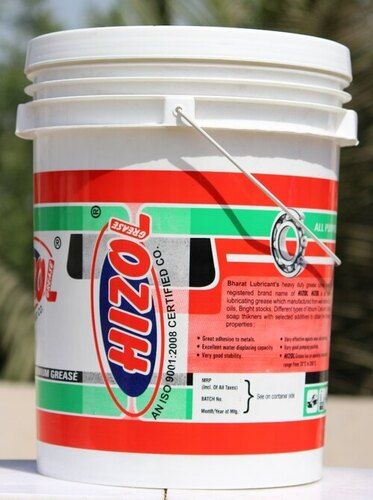

Lithium Nlgi Ap 2 Grease 18 KG

Price 5697 INR/ Unit

Lithium Nlgi Ap 2 Grease 18 KG Specification

- Water Content Vol%

- <0.1%

- Oil Type

- Mineral Oil Base

- Type

- Lithium Based

- Use

- Industrial

- Viscosity

- 100 cSt at 40C

- Density

- 0.91 Gram per cubic centimeter(g/cm3)

- Weight

- 18 KG Kilograms (kg)

- Application

- Automotive bearings, industrial bearings, universal joints, chassis lubrication

- Chemical Composition

- High-quality mineral oil, lithium soap thickener, additives

- Operating Temperature

- -20C to +120C Celsius (oC)

- Smell

- Mild petroleum odor

- Color

- Off White

- Grease

- NLGI Grade 2

- Packaging Type

- Bucket

- Ash %

- <0.8%

- Size

- 18 KG

- Vehicle Type

- Automobile, Industrial Machinery

- Pack Type

- Bucket

- Water Resistance

- Good

- Timken OK Load

- 16 kg (min)

- Shelf Life

- 24 months from manufacturing date

- Oxidation Stability

- High

- Corrosion Protection

- Excellent

- Soap Type

- Lithium Soap

- Storage Conditions

- Store in a cool, dry place away from direct sunlight

- Penetration Worked (60x, 25C)

- 265-295

- Shear Stability

- Good

- Drop Point

- >190C

Lithium Nlgi Ap 2 Grease 18 KG Trade Information

- Minimum Order Quantity

- 100 Units

- Payment Terms

- Cash Advance (CA)

- Supply Ability

- 10000 Units Per Day

- Delivery Time

- 4 Days

- Packaging Details

- 18 KG BKT

- Main Domestic Market

- All India

- Certifications

- ISO Certified

About Lithium Nlgi Ap 2 Grease 18 KG

BHARAT LITHON AP RANGE GREASE is a top-tier lubricating grease, meticulously crafted for the automotive and industrial sectors. It employs an optimized blend of superior base oils, lithium-complex thickener technology, and high-performance additives to ensure exceptional performance and protection.Application:

BHARAT LITHON AP RANGE GREASE is recommended for application in the wheel bearings of various vehicles, including passenger cars, trucks, buses, farm equipment, as well as both on-highway and off-highway commercial vehicles and machinery.

Performance Benefits:

- Wide operating temperature range

- Good resistance to water washout

- Extra protection against rust and corrosion

- Excellent structural stability

- Exhibit excellent film forming characteristics and are

- therefore also effective as protective greases for

- chassis and other applications.

Typical Data Specifications:

| SR. NO. | CHARACTERISTICS | TEST | UNIT | RANGE |

| 1 | Soap Type | - | - | Lithium |

| 2 | NLGI Grade | - | - | 2 |

| 3 | Colour | VISUAL | - | Off White |

| 4 | Texture | - | - | Short fibre, Smooth & Buttery |

| 5 | Penetration at 25 C Worked, | ASTM D.217 | mm1 | 260-295 |

| 6 | Water Washout at 80 C, % | ASTM D.1264 | - | Less than 3 |

| 7 | Dropping Point, C | ASTM D.2265 | C | 180C-190C |

| 8 | Operating Temperature, C | ASTM D.2265 | C | 140C |

Versatile Industrial and Automotive Lubrication

Lithium NLGI AP 2 Grease is designed for heavy-duty performance in a variety of environments, including automotive and industrial applications. Its lithium soap formulation provides optimal protection for bearings, universal joints, and chassis, ensuring smooth operation under both high load and temperature variations. The grease's high oxidation stability and robust corrosion resistance extend the life of mechanical components.

High-Temperature Performance and Stability

With a drop point exceeding 190C and an operating temperature range from -20C to +120C, this lithium grease maintains its structure and lubricity even under harsh conditions. Its high viscosity and minimal water content (<0.1%) ensure consistent performance and protection against wear, while the off-white, mineral oil-based formula resists breakdown, prolonging maintenance intervals.

FAQ's of Lithium Nlgi Ap 2 Grease 18 KG:

Q: How should Lithium NLGI AP 2 Grease be applied for best results?

A: It is recommended to clean the application area thoroughly before use. Apply the grease directly on bearings, universal joints, or chassis parts using suitable dispensing equipment, ensuring even coverage for optimal lubrication and protection.Q: What types of machinery or vehicles can use this grease?

A: This grease is ideal for both industrial machinery and automobiles. Common applications include automotive bearings, industrial bearings, universal joints, and chassis lubrication. Its high load-bearing capacity makes it suitable for heavy-duty and high-performance environments.Q: When should I reapply Lithium NLGI AP 2 Grease for maintenance?

A: Reapplication interval depends on the operating conditions and manufacturer recommendations. In general, regular maintenance schedules ranging from weekly to monthly are advised, especially in high-load or high-temperature operations to maintain optimal equipment performance.Q: Where should the grease be stored for maximum shelf life?

A: Store the 18 KG bucket in a cool, dry place, away from direct sunlight. Proper storage conditions help preserve the grease's properties, ensuring up to 24 months of usability from the date of manufacture.Q: What are the benefits of using a lithium soap-based grease compared to others?

A: Lithium soap-based greases offer superior water resistance, excellent corrosion protection, high oxidation stability, and good shear stability. This ensures reliable lubrication, reduced wear, and extended service intervals under demanding operating conditions.Q: How does the grease maintain performance under water or high-moisture conditions?

A: With good water resistance and a water content below 0.1%, the grease forms a protective barrier against moisture, preventing rust and extending the lifespan of machinery components even in wet environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Grease Category

Graphited Calcium Grease 18 KG

Price 4337 INR / Unit

Minimum Order Quantity : 100 Units

Use : Industrial

Type : Calcium Based

Pack Type : Bucket

Color : Black

Premium Long Life Lithium-Based Grease 18 KG

Price 6398 INR / Unit

Minimum Order Quantity : 100 Units

Use : Industrial

Type : Lithium Based

Pack Type : Bucket

Color : Red

Ep2 Grease Calcium Based 18 kg

Price 4167 INR / Unit

Minimum Order Quantity : 100 Units

Use : Industrial

Type : Calcium Based

Pack Type : Bucket

Color : Lemon yellow

Golden Gel Grease Lithium-Based 18 KG

Price 5867 INR / Unit

Minimum Order Quantity : 100 Units

Use : Industrial

Type : Lithium Based

Pack Type : Bucket

Color : Golden

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese