Graphited Calcium Grease 18 KG

Price 4337 INR/ Unit

Graphited Calcium Grease 18 KG Specification

- Density

- 0.90 Gram per cubic centimeter(g/cm3)

- Water Content Vol%

- Less than 1.0%

- Grease

- Graphited Calcium Grease

- Packaging Type

- Plastic bucket with lid

- Type

- Calcium Based

- Viscosity

- Semi-fluid to moderately stiff

- Color

- Black

- Weight

- 18 KG Kilograms (kg)

- Smell

- Characteristic mineral oil smell

- Operating Temperature

- -10C to 60C Celsius (oC)

- Chemical Composition

- Calcium soap base, graphite, mineral oils

- Application

- General purpose lubrication, chassis, water pumps, industrial bearings

- Ash %

- Approximately 1.5-2.0%

- Use

- Industrial

- Oil Type

- Mineral Oil

- Size

- 18 KG Bucket

- Pack Type

- Bucket

- Vehicle Type

- Suitable for industrial machinery and automotive applications

- Penetration (Worked, 60 Strokes)

- 265-295

- NLGI Grade

- 2

- Corrosion Protection

- Yes

- Drop Point

- More than 80C

- Storage Instructions

- Store in cool, dry place, away from direct sunlight

- Compatibility

- Compatible with most calcium and mineral oil-based greases

- Consistency

- Smooth and adhesive

- Additives

- Graphite for enhanced lubrication and load bearing

- Water Resistance

- Excellent

- Shelf Life

- 24 months from manufacture date

Graphited Calcium Grease 18 KG Trade Information

- Minimum Order Quantity

- 100 Units

- Payment Terms

- Cash Advance (CA)

- Supply Ability

- 10000 Units Per Day

- Delivery Time

- 4 Days

- Packaging Details

- 18 KG BKT

- Main Domestic Market

- All India

- Certifications

- ISO Certified

About Graphited Calcium Grease 18 KG

BHARAT GRAPHITE CALCIUM BASED GREASE is an all-purpose lubricating grease, manufactured from well- refined base oils and a Calcium soap thickener & Graphite, with selected additives.Application:

BHARAT GRAPHITE CALCIUM BASED GREASE is used for the lubrication of all General Operations in industries and is also applicable for the lubrication of universal joints, and chassis pivots of vehicles.

- Grease Calcium Graphite 0 has been designed specifically for the lubrication of rails in railways mainly in the curve and other areas exposed to major friction, to avoid the early wear of both the wagon wheel and the rails.

- Grease Calcium Graphite 3 is intended for lubrication of the pantograph sheet iron as conductive calcium grease

Performance Benefits:

Good stability

Effective against wear and corrosion

Good pumping qualities.

Calcium based graphite grease for severe operating conditions. Temperature range 20 up to 120 C.

Typical Data Specifications:

| SR. NO. | CHARACTERISTICS | TEST | UNIT | RANGE |

| 1 | Soap Type | - | - | Calcium |

| 2 | NLGI Grade | - | - | 2.5 |

| 3 | Colour | VISUAL | - | BLACK |

| 4 | Texture | - | - | Short fibre, Smooth & Buttery |

| 5 | Penetration at 25 C Worked, | ASTM D.217 | mm1 | 220-295 |

| 6 | Water Washout at 80 C, % | ASTM D.1264 | - | Less than 3 |

| 7 | Dropping Point, C | ASTM D.2265 | C | 100C-110C |

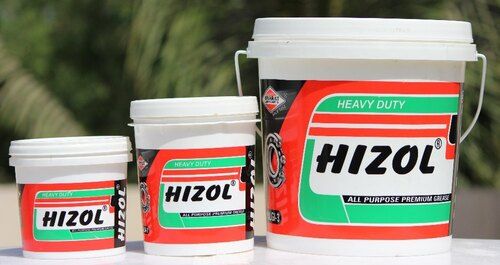

Available Packing Sizes: 100 GM, 200 GM, 250 GM, 500 GM, 1 KG, 2 KG, 3 KG, 5 KG, 7 KG, 10 KG, 18 KG, 50 KG, 100 KG, 180 KG.

Enhanced Lubrication with Graphite Technology

Infused with graphite, this calcium-based grease significantly improves lubricity and load-bearing properties. The added graphite particles help reduce friction and wear on metal surfaces, even in heavily loaded or slow-moving equipment, ensuring longer component life and smoother operation. Ideal for demanding industrial and automotive settings, it outperforms standard greases under high stress.

Reliable Protection Against Water and Corrosion

This grease exhibits remarkable water resistance, making it especially effective for applications prone to moisture-such as water pumps and exposed machinery. Its unique formulation offers outstanding corrosion protection, helping preserve metal surfaces and mechanical integrity even in humid or wet environments. Its strong adhesive nature ensures it remains in place for sustained protection.

FAQ's of Graphited Calcium Grease 18 KG:

Q: How should Graphited Calcium Grease 18 KG be stored for optimal shelf life?

A: For best results, store this grease in a cool, dry location away from direct sunlight. Ensure the lid is tightly closed to prevent contamination. Under suitable storage conditions, the product maintains quality for up to 24 months from the manufacturing date.Q: What are the main industrial and automotive uses for this grease?

A: It is designed for general-purpose lubrication, such as in chassis, water pumps, and industrial bearings. Its robust additive package and water resistance make it suitable for a wide range of industrial machinery and automotive maintenance tasks.Q: When should I use Graphited Calcium Grease instead of regular calcium or mineral oil greases?

A: Choose this grease when enhanced load carrying, water resistance, and superior lubrication are important-especially in environments exposed to moisture, vibration, or heavy-duty operations where standard greases may fail.Q: Where is this product typically applied within industrial machinery?

A: It is commonly applied to bearings, moving joints, water pumps, chassis points, and other friction-prone areas within industrial and automotive equipment, ensuring those components are lubricated and protected from corrosion.Q: What is the process for applying this grease to machinery or vehicles?

A: Clean the lubrication points of old grease or debris. Apply the Graphited Calcium Grease directly from the bucket using a grease gun or suitable applicator, ensuring all moving parts are adequately coated. Regular reapplication depends on operational demands and maintenance schedules.Q: What benefits does the graphite additive provide in this grease?

A: The graphite enhances lubrication under high-load conditions, reduces friction, and helps prevent metal-to-metal contact-even if the lubrication film is momentarily broken. This leads to better protection, smoother performance, and increased lifespan of components.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Grease Category

Ep 2 Grease Lithium Based Grease 18 KG

Price 5824 INR / Unit

Minimum Order Quantity : 100 Units

Pack Type : Bucket

Application : Bearings, Chassis, Industrial Machinery

Chemical Composition : Lithium Soap Thickener, Mineral Oil, Additives

Size : 18 KG

Ep 1 Grease Lithium Based Grease

Price 3285 INR / Unit

Minimum Order Quantity : 100 Units

Pack Type : Bucket

Application : Bearings, Universal Joints, Chassis Lubrication

Chemical Composition : Lithium Soap Thickener with Additives

Size : 18 kg, 50 kg, 180 kg

High Temperature Heavy Load Grease

Price 4087 INR / Unit

Minimum Order Quantity : 100 Units

Pack Type : Bucket

Application : High Temperature, Heavy Load Bearings

Chemical Composition : Complex Lithium Soap, Additives

Size : 20 L

mp3 shuttering Red Grease

Price 1600 INR / Unit

Minimum Order Quantity : 100 Units

Pack Type : Bucket

Application : Shuttering, Construction Machinery Lubrication

Chemical Composition : Calcium Soap, Mineral Oil, Red Pigment

Size : Available in various sizes

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese