Ep000 Grease Lithium-Based 18 KG

Price 6504 INR/ Unit

Ep000 Grease Lithium-Based 18 KG Specification

- Ash %

- <1.0%

- Viscosity

- NLGI 2 (Approximate)

- Type

- Lithium Based

- Color

- Off White

- Oil Type

- Mineral Oil

- Packaging Type

- Bucket

- Water Content Vol%

- <0.1%

- Application

- Multipurpose, Wheel Bearings, Chassis Lubrication

- Grease

- EP000

- Chemical Composition

- Lithium Soap Thickener, Mineral Base Oil

- Weight

- 18 KG Kilograms (kg)

- Density

- 0.90 Gram per cubic centimeter(g/cm3)

- Operating Temperature

- -20C to +120C Celsius (oC)

- Use

- Industrial

- Smell

- Mild

- Size

- 18 KG

- Vehicle Type

- Industrial Machinery, Automobiles

- Pack Type

- Bucket

- Soap Type

- Lithium

- Corrosion Resistance

- Excellent

- Dropping Point

- Above 180C

- Shear Stability

- High

- Penetration Worked (60 Strokes)

- 355-385 (ASTM D217)

- Water Washout Resistance

- Good (ASTM D1264)

- Texture

- Smooth and Homogeneous

Ep000 Grease Lithium-Based 18 KG Trade Information

- Minimum Order Quantity

- 100 Units

- Payment Terms

- Cash Advance (CA)

- Supply Ability

- 10000 Units Per Day

- Delivery Time

- 4 Days

- Packaging Details

- 18 KG BKT

- Main Domestic Market

- All India

- Certifications

- ISO Certified

About Ep000 Grease Lithium-Based 18 KG

BHARAT LITHON EP000 GREASE is a premium lithium complex soap based grease of 0 consistency, crafted from highly refined mineral oils infused with extreme pressure and EP additives. With a high drop point and excellent roll stability, it boasts superior resistance to water washout, a low coefficient of friction, and exceptional load-carrying capacity.Application:

Recommended for lubrication requirements where NLGI 000 grade is recommended with EP properties.Performance Benefits:Bharat LITHON EP 000 series of lubricants are high-quality lithium soap greases designed for lubricating a wide range of mechanical equipment. These superior multipurpose greases are developed to meet the diverse needs of bearing manufacturers.

Typical Data Specifications:

| SR. NO. | CHARACTERISTICS | TEST | UNIT | RANGE |

| 1 | Soap Type | - | - | Lithium |

| 2 | NLGI Grade | - | - | 000 |

| 3 | Colour | VISUAL | - | Off White |

| 4 | Texture | - | - | Short fibre, Smooth & Buttery |

| 5 | Penetration at 25 C Worked, | ASTM D.217 | mm1 | 445-475 |

| 6 | Water Washout at 80 C, % | ASTM D.1264 | - | Less than 3 |

| 7 | Dropping Point, C | ASTM D.2265 | C | - |

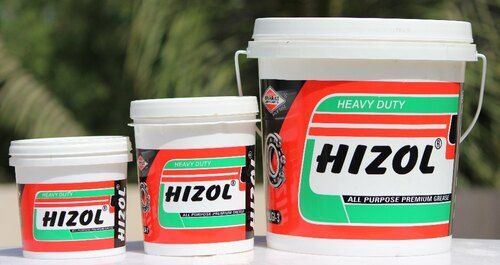

Available Packing Sizes: 18 KG, 50 KG, 100 KG, 180 KG.

Outstanding Protection and Versatility

Ep000 Grease is renowned for its exceptional corrosion resistance and high shear stability, making it a reliable choice for heavy-duty industrial machinery and automobiles. Its wide operating temperature range ensures consistent lubrication and protection, even in challenging environments. The multipurpose formulation adapts seamlessly to various lubrication needs, offering lasting value and proven durability.

Engineered for Performance and Longevity

With a dropping point above 180C and water content under 0.1%, this lithium-based grease provides a stable barrier against moisture and heat. The mineral oil base, combined with lithium soap thickener, helps reduce wear and extend equipment life. Its smooth texture allows for easy application, whether used in wheel bearings, chassis points, or complex machinery.

FAQ's of Ep000 Grease Lithium-Based 18 KG:

Q: How should Ep000 Lithium-Based Grease be applied for optimal results?

A: Apply the grease directly to clean bearing surfaces, chassis lubrication points, or multipurpose lubrication areas using a suitable applicator. Ensure surfaces are free from old grease and contaminants for the best results.Q: What benefits does the high shear stability of this grease offer?

A: High shear stability ensures the grease maintains its structure under mechanical stress, reducing the need for frequent reapplication and providing consistent lubrication over extended periods.Q: When is this grease most effectively used in industrial or automotive settings?

A: It is most effective during routine maintenance or when assembling new machinery, particularly for wheel bearings, chassis lubrication, and other moving parts subject to friction and wear.Q: Where is Ep000 Grease typically utilized within various industries?

A: This grease is widely used in industries such as automotive manufacturing, heavy machinery, material handling equipment, and other sectors requiring reliable, multipurpose lubrication.Q: What steps should be followed in the lubrication process with this product?

A: Start by cleaning the lubrication point, remove debris and old grease, then apply Ep000 Grease evenly. Operate the machine briefly to ensure even distribution and check for leaks or excess grease.Q: What are the key usage precautions for Ep000 Grease?

A: Avoid mixing with other grease types to preserve performance. Store in a cool, dry place with the bucket tightly sealed to prevent contamination. Dispose of waste grease responsibly.Q: What are the principal benefits of using Ep000 Grease in industrial applications?

A: The grease offers excellent protection against corrosion, water washout, and mechanical wear. Its smooth texture and high dropping point ensure reliable operation across a broad temperature range, extending equipment life and reducing downtime.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Grease Category

Lithium Based Ap3 Grease 18 KG

Price 5760 INR / Unit

Minimum Order Quantity : 100 Units

Weight : 18 KG Kilograms (kg)

Operating Temperature : 20C to 130C Celsius (oC)

Smell : Mild/Oily

Pack Type : Bucket

Ep 2 Grease Lithium Based Grease

Price 3355 INR / Unit

Minimum Order Quantity : 100 Units

Weight : 18 kg Kilograms (kg)

Operating Temperature : 20C to +130C Celsius (oC)

Smell : Mild

Pack Type : Bucket

High Temperature Grease 300 Degree Temp

Price 4087 INR / Unit

Minimum Order Quantity : 100 Units

Weight : 5 Kg Kilograms (kg)

Operating Temperature : 20C to 300C Celsius (oC)

Smell : Mild Petroleum

Pack Type : Bucket

Ep000 Grease Lithium-Based

Price 3355 INR / Unit

Minimum Order Quantity : 100 Units

Weight : Varies by Pack Size Kilograms (kg)

Operating Temperature : 20C to +120C Celsius (oC)

Smell : Characteristic Petroleum Odor

Pack Type : Bucket

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese